Cattle Feed Process Flow Chart Flowchart Examples

The production process for premixes and mixed feeds should be described in a flow chart. The flow chart should show that the production equipment used for production of feeds containing prohibited materials is separated from that used for production of other categories of feed, depending on the feed ban in place, as described in the "Over-

Mobile Intelligent Poultry Feed Dispensing System Flowchart Download

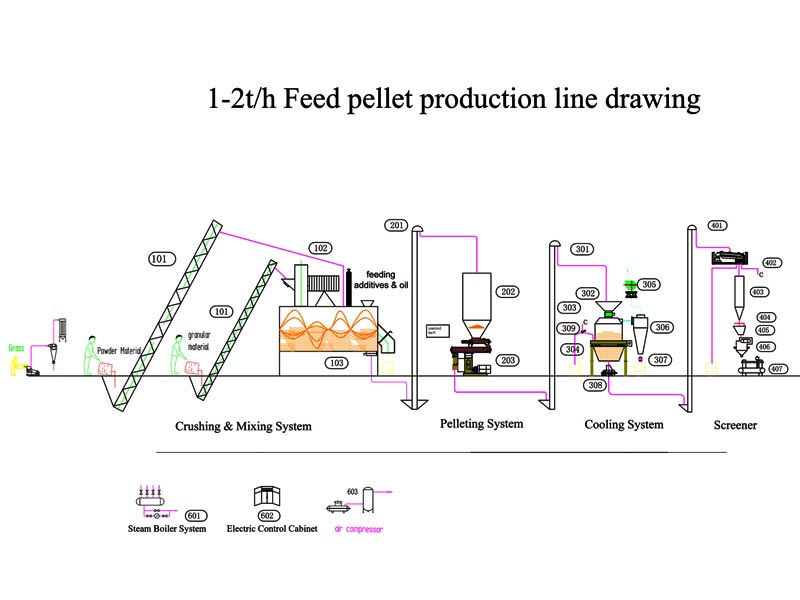

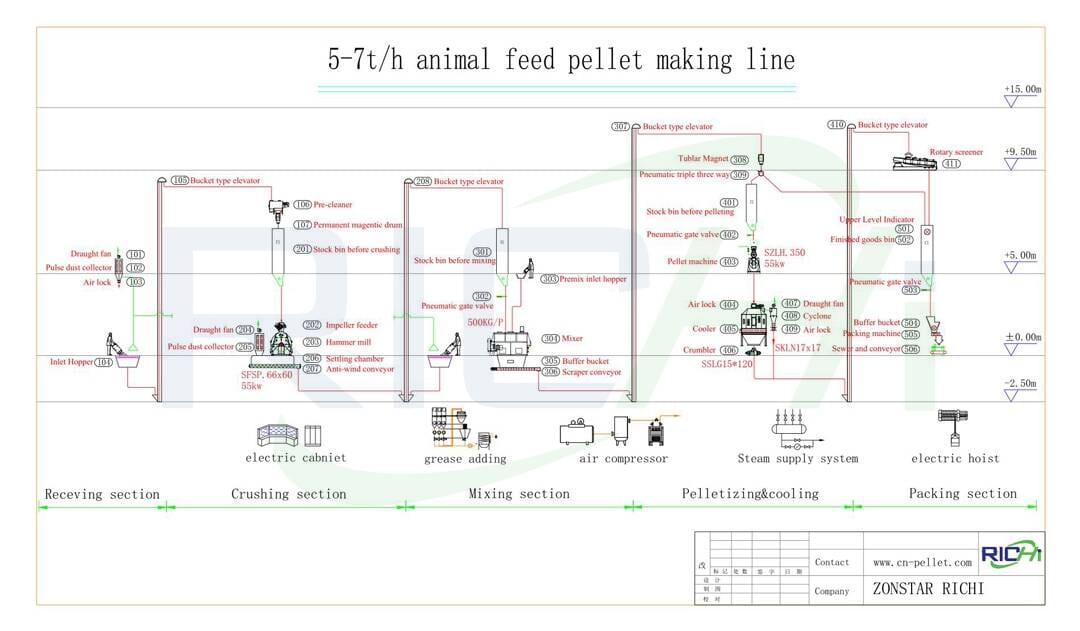

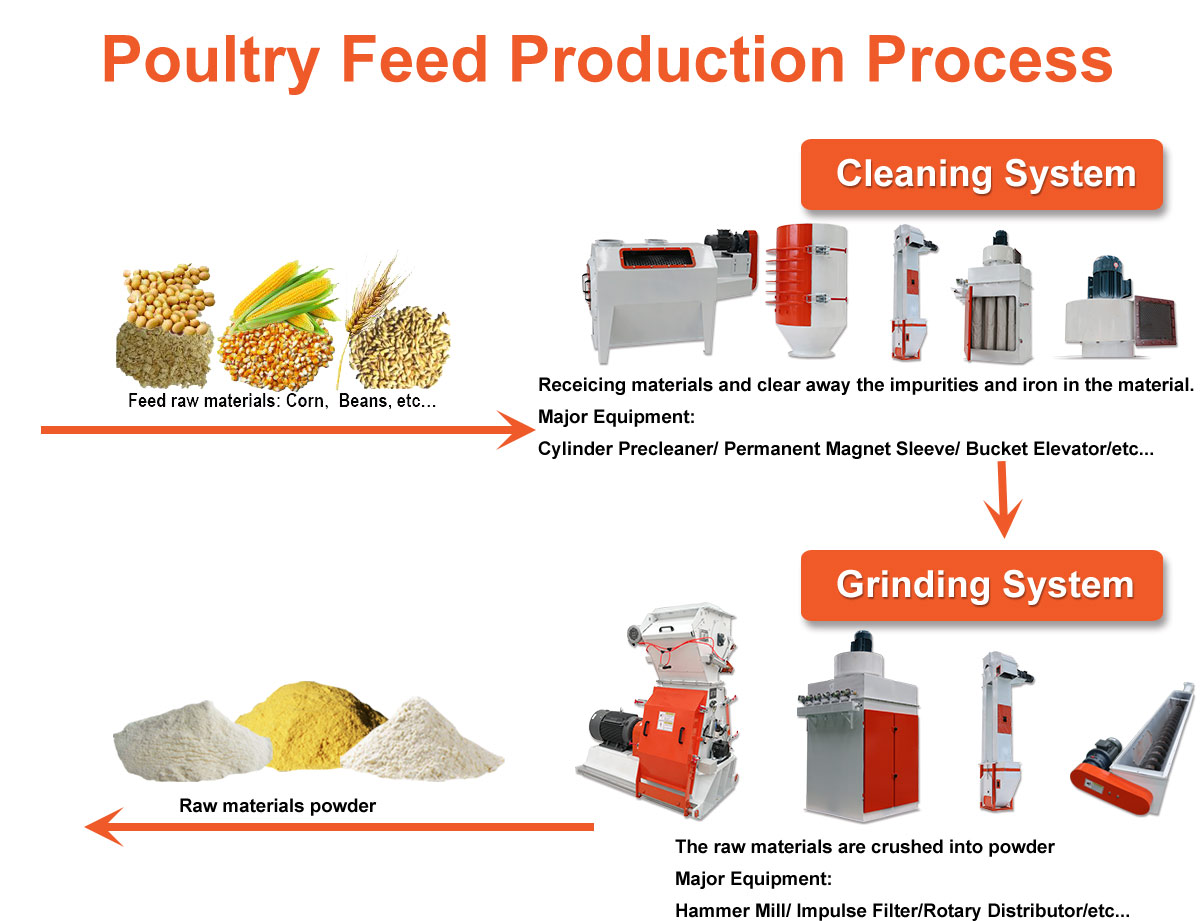

Poultry feed manufacturing process flow chart. The processing of composite poultry feed is usually divided into the following steps: receiving and cleaning of raw materials, crushing of raw materials, batching, mixing, pelleting and packaging. The diameter of the final feed pellets can be 2 to 8 mm.

Poultry Feed Manufacturing Process Flow Chart Labb by AG

1. INTRODUCTION 2. RECEIVING 3. PROCESSING 4. PACKAGING 5. STORAGE AND DISTRIBUTION 1/ Lecture was presented by G. Walker P. Raven and G. Walker Western Farmers Association Seattle, Washington 1. INTRODUCTION The technology of feed processing has undergone substantial improvement in recent years.

Poultry Feed Manufacturing Process Flow Chart (2022)

The production of poultry feed consists of five main work stages: the receiving, grinding, mixing, pellet and warehouse. The pellet process represents the heart of the manufacturing.

57T/H Poultry Feed Production Line, Complete Poultry Feed Plant RICHI

Poultry feed manufacturing process flow chart The processing of composite poultry feed is usually divided into the following steps: receiving and cleaning of raw materials, crushing of raw materials, batching, mixing, pelleting and packaging. The diameter of the final feed pellets can be 2 to 8 mm.

Flow_Poultry

Representative samples of different animal manures, chicken feather, and poultry litter were also subjected to a pyrolysis process. Poultry litter had the highest heating value (19.48 MJ/kg) among.

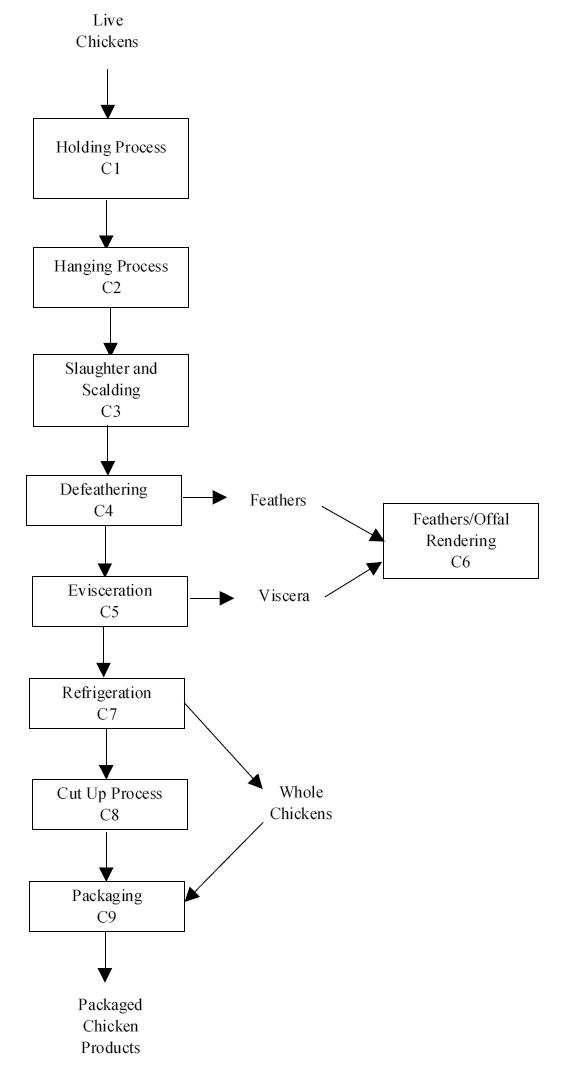

The poultry production process at a glance. Download Scientific Diagram

The study aims to investigate the effects of some operating parameters (pressure and temperature of the compounded feed) and die hole size on the pelleting efficiency, throughput capacity, and to.

Feed mill process map Download Scientific Diagram

A Flow Chart was established for continuous improvement in pellet process for any feed manufacturing plant as shown in fig-17. Figure -17, Flow chart for feed test.

Poultry factory's process flow diagram. Download Scientific Diagram

Conclusion. Feed manufacturing processes are a symphony of science and engineering, where raw materials are transformed into nutritionally balanced feeds that drive the livestock and poultry industry. Process engineers are pivotal in optimizing these processes, ensuring efficiency, consistency, and compliance with stringent quality and safety.

The poultry production process at a glance. Download Scientific Diagram

INTRODUCTION Feed manufacturing and the associated quality control programme are keys to successful fish culture. Unless the fisheries biologist understands and specifies the activities of the feed mill and its laboratory, profitable fish farming will be a matter of chance.

Poultry Feed Manufacturing Process Flow Chart (2022)

Among the process, the systems of receiving and storage of raw materials, the production and expedition process of the feed were evaluated, as well as the management, control quality, supply water.

Poultry factory's process flow diagram. Download Scientific Diagram

1. of Manufacturing: The ingredients are pulverized in a pulverizes to the required mesh size. The product is mixed and meshed in a vibrating screen to ensure correct particle size. The product is packed in ordinary gunny bags or polythene lined gunny bags. 2.Quality Specification As per the Govt. specification 3.Production Capacity per annum

Example of Poultry Processing HACCP Flow Diagram. Download Scientific

Wide applicable scope: The poultry chicken feed production line can produce both poultry & livestock feed and fish feed and is applicable for medium and small sized feed mills and breeding farms. however, for fish feed, it makes sinking type fish feed, if you want to make floating type, you can use floating fish feed production line or a small f.

Flow diagram of preparation of Chicken roasted. Download Scientific

What is Feed Milling? Feed milling is the process of grinding and processing feed ingredients into a form that is suitable for animal consumption. The feed milling process can be divided into five main stages: raw material handling, grinding, mixing, pelleting, and cooling.

Poultry Feed Production Line

Step 01: Raw Materials Reception and Cleaning Process The first stage involves receiving and cleaning the raw material such as grain, beans, grass or fish meals used for making pellet feed. Step 02: Feed Crushing Process The material is then passed into the hammer mill, where it is ground into a size which is suitable for making feed pellets.

Animal Feed manufacturing plant,how animal feed mill plant build? the

Detailed Pellet Production of Poultry Feed Manufacturing Process. Step 1: Collection of the raw materials required for feed production and they arrive in sacks or bags to the feed plant. The ingredients are identified, sorted out and their condition assessed. The ingredients in the sacks are stored in a dry place free from rodents and insects.